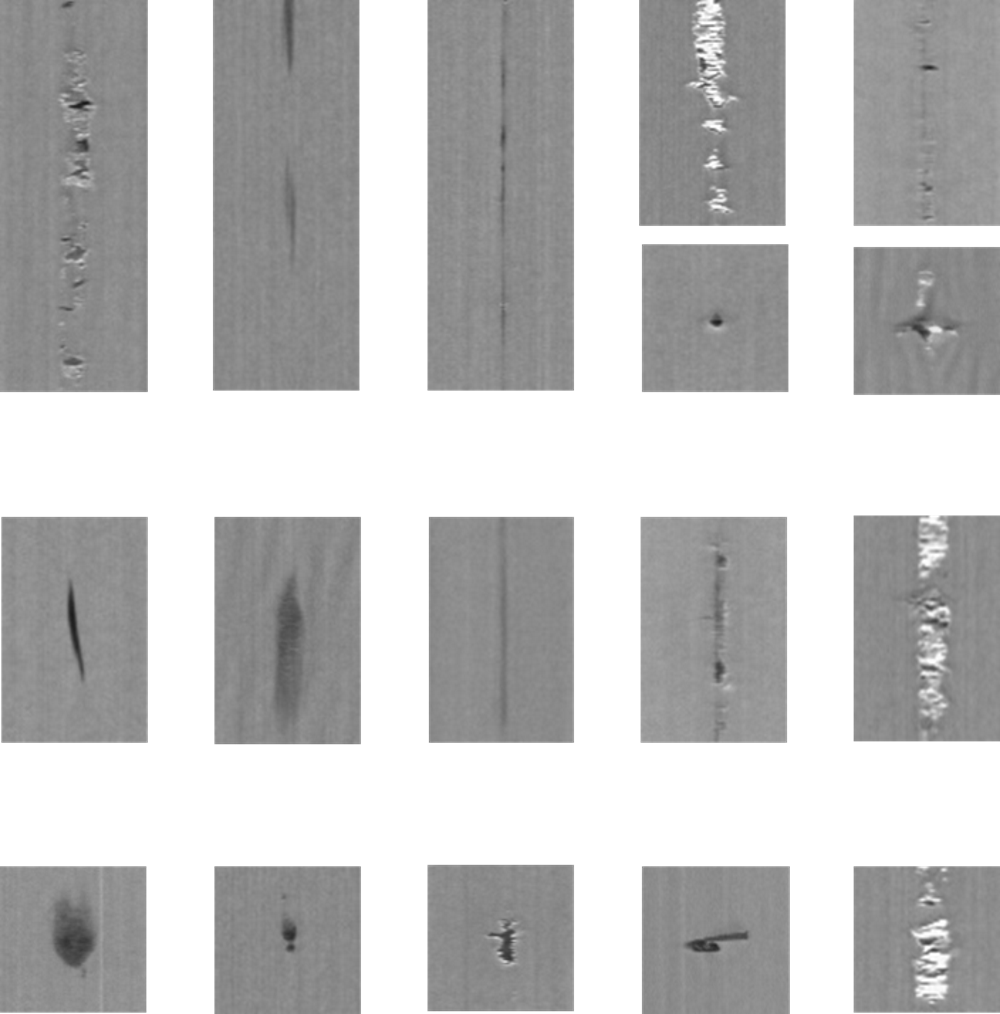

The stretching process can induce some surface defects such as stains, marks, scratches or bright marks.

The most critical defects are very thin and can’t be seen during the on-line process.

Flat-rolled aluminium and steel producers are facing a trend towards zero-defect tolerances regarding surface quality.

Automatic online inspection is strongly required in replacement of inspection carried out manually via physical sampling.

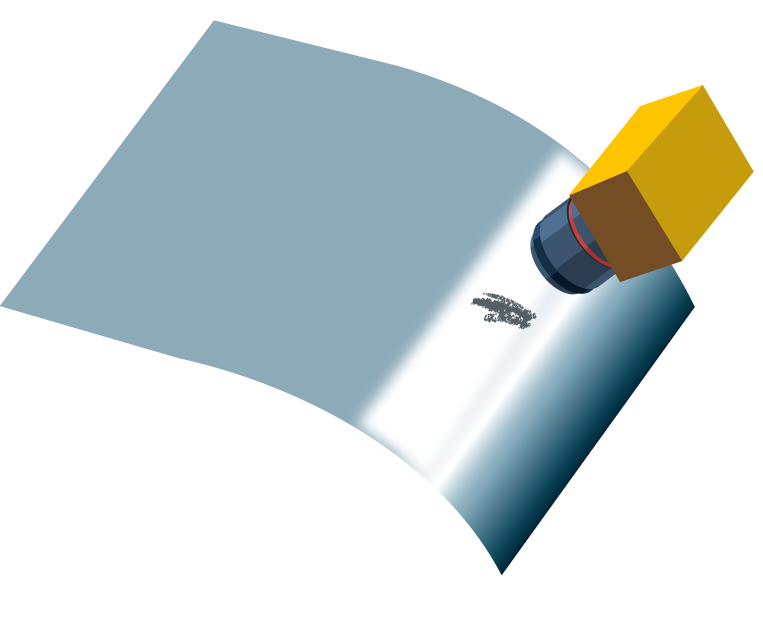

Controlling the quality surface during the final phases of the process certifies a high level of quality and also prevents defective material from being further processed. VEGA range is offering automatic detectors designed to inspect 100% of the foils for the highest quality assurance.

Your benefits

Our commitment

Decisive advantages for securing your position vis-à-vis your clients and beyond your competitors

- Productivity: no speed reduction for quality control, improved real-time process control

- Availability and cost-saving: identification of preventive maintenance, reduced rejects and customer claims

- Quality: certified quality with detection and classification of defects; customer satisfaction

- Efficiency and accuracy: early detection before value-adding processes, inspection of 100% of the strip

- Reliability and predictability: special design and robustness for severe environments, insensitivity to ambient light

Accurate and Robust

The sensor technology, its specific design and ruggedness are approved for severe environments; ambient light immunity.

Certified by Arck Sensor

“We are committed to offering robust and accurate products of the highest quality.”

Eric Rumeau, President

Eric Pautal, General Manager