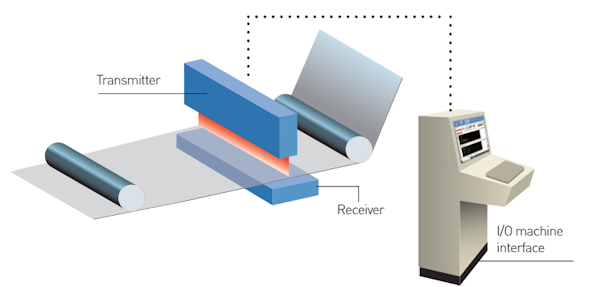

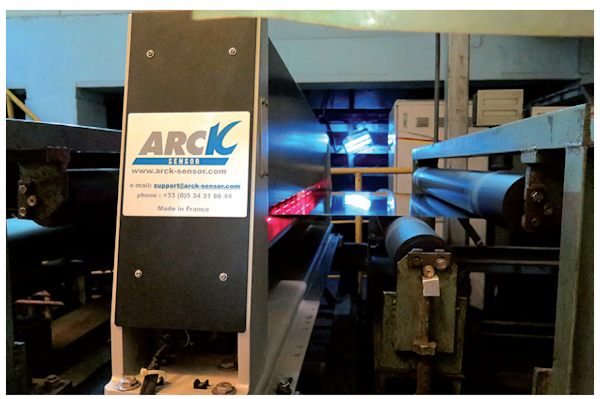

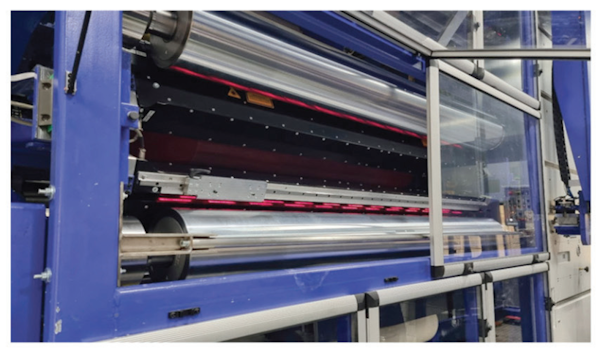

Pinhole detection on single-rolled metal strips and foils with CEPHEE® V

Pinhole detectors of our CEPHEE range are offering accurate automatic on-line inspection equipments to certify your manufacturing of metal flat-rolled products.

Our pinhole detector of the latest generation CEPHEE® V is a cutting-edge detector able to analyse 100% of the single-rolled strips (thickness in the range 0.1 – 6 mm) at a high speed. It can be used also for metal thinner gauges. It detects circular holes of 10µm diameter minimum at a speed of 600 meters per minute.

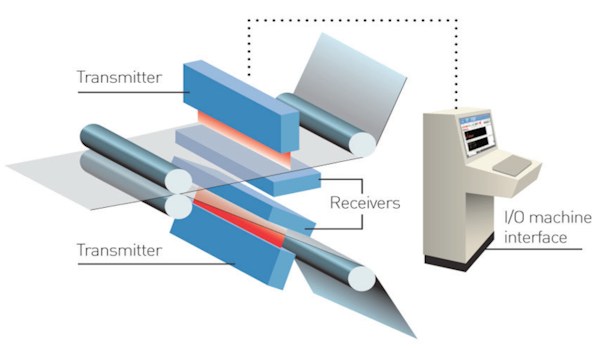

Pinhole detection on double-rolled aluminium foils with CEPHEE®ASL

For the very thinnest gauges (6-70µm), the foil is doubled to avoid breakage because of the extreme thinness in the cold rolling mill, then rolled to the desired gauge and separated into large reels; to be later slitted to required widths.

CEPHEE®ASL is an automatic detector especially designed for double-rolled foils, testing 100% of the two foils at the exit of the separator.

It detects circular holes of 10µm diameter minimum at a speed of 1200 meters per minute and indicates the exact location of each detected pinhole.

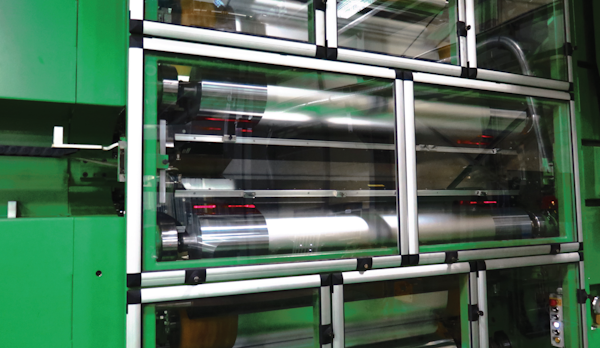

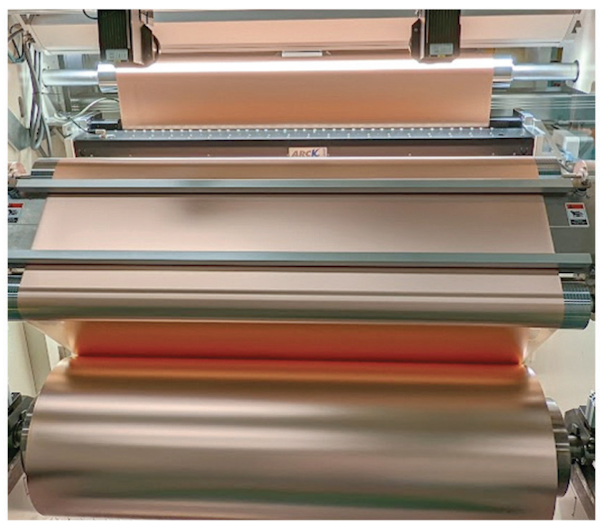

Pinhole detection on single-rolled aluminium and/or copper foils with CEPHEE®SSL

CEPHEE ®SSL also available for single laminated aluminium or copper foils (designed for slitters).

It detects circular holes of 10µm diameter minimum at a speed of 1200 meters per minute and indicates the exact location of each detected pinhole.