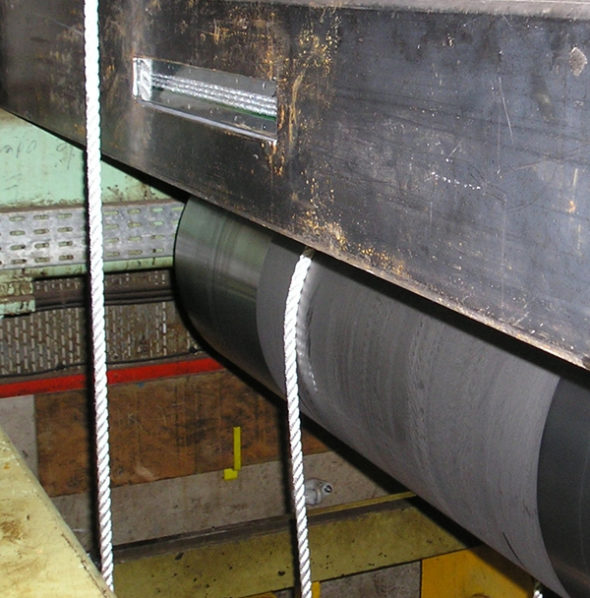

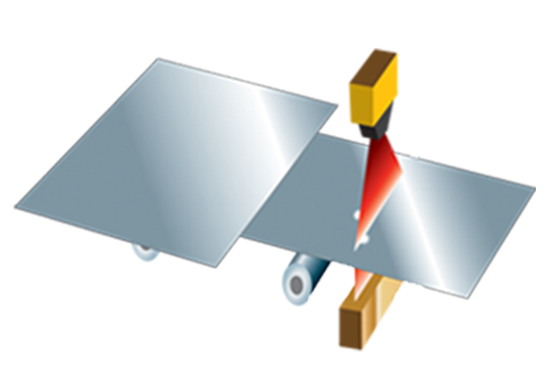

Prior entering continuous processing lines such as tinning or annealing lines, metal strips are joined together by a weld seam forming an endless strip that runs continuously.

A single coil may contain a number of welds which should be indicated clearly, usually by punching of a hole before the weld seam. Detecting a hole is then always connected with the fact that a weld seam follows after this hole at a specific distance. This detection allows slowing down or stopping the line in case of joined sheets with different widths or thicknesses or grades; to prevent a coiling/uncoiling breakout of the strip leading to damages and injuries.

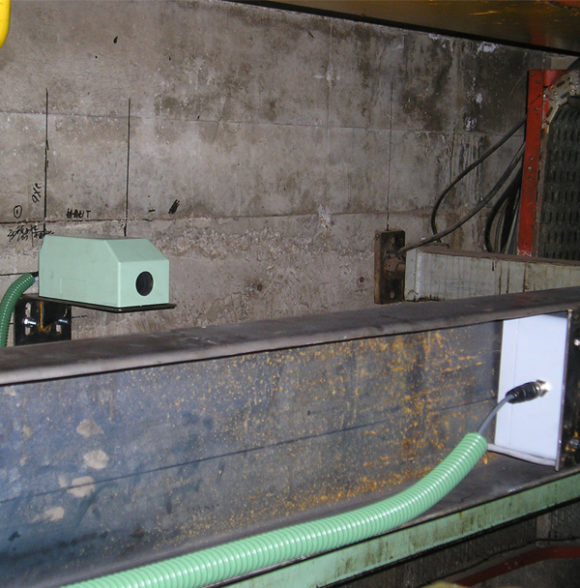

Our SIRRAH® sensor is working with a specific infrared light emitter to detect punched hole continuously and permanently at a high speed.

Your benefits

Our commitment

Decisive advantages for securing your position vis-à-vis your clients and beyond your competitors

- Productivity: improved real-time process control

- Availability and cost-saving: less down time, reduced rejects and customer claims

- Quality: customer satisfaction

- Efficiency and accuracy: continuous detection

- Reliability and predictability: special design and robustness for severe environments, continuous operation even in harsh ambient conditions, insensitivity to ambient light

Accurate and Robust

The sensor technology, its specific design and ruggedness are approved for severe environments; ambient light immunity.

Certified by Arck Sensor

“We are committed to offering robust and accurate products of the highest quality.”

Marc Brouant, President