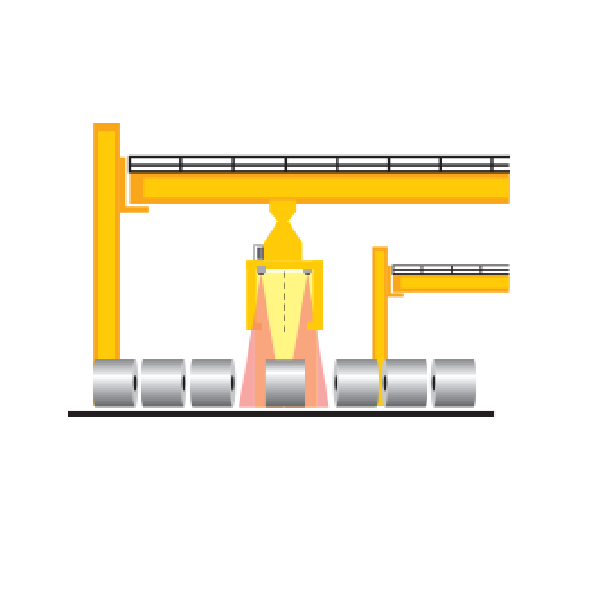

SPICA® is an optical sensor which can be used for coil detection prior to handling with an OHB crane.

It can be integrated into an automated system or as a help to the crane operator with a simple display.

This solution has been proven to improve performance and decrease cost by decreasing waste due to damage done during handling, while improving safety for employees and facilities.

Your benefits

Our commitment

Decisive advantages for securing your position vis-à-vis your clients and beyond your competitors

- Productivity: shorter cycle times, faster operations

- Safety: enhanced prevention of accidents or collisions for people, materials and equipments; reduced stress and fatigue on the crane operator as well as on hoisting equipment

- Availability and cost-saving: less premature wear and tear, reduced time loss waiting for load movement, lower operational and maintenance costs, decreased waste due to damage during handling

- Quality: reduced Customer claims and material damages while handling

- Efficiency and accuracy: precise and safe handling

- Reliability and predictability: special design and robustness for severe environments, continuous operation even in harsh ambient conditions

- Sustainability: minimized waiting times thus reducing energy consumption and related CO2 emissions

Accurate and Robust

The sensor technology, its specific design and ruggedness are approved for severe environments; ambient light immunity.

Certified by Arck Sensor

“We are committed to offering robust and accurate products of the highest quality.”

Eric Rumeau, President

Eric Pautal, General Manager